The Latest Technology of Solder Paste Printing

This article introduces that even the best solder paste, equipment and application method may not fully guarantee acceptable results. Users must control the process and equipment variables to achieve good printing quality.

In the reflow soldering of surface mount assembly, solder paste is used for the connection between the pins or terminals of surface mount components and pads. There are many variables, such as solder paste, screen printing machine, solder paste application method and printing process. In the process of printing solder paste, the base plate is placed on the workbench, clamped and positioned mechanically or vacuum, and aligned with locating pins or vision. SMT steel mesh is used for solder paste printing. This paper will focus on several key solder paste printing issues, such as stencil design and printing process.

1) Printing process and equipment

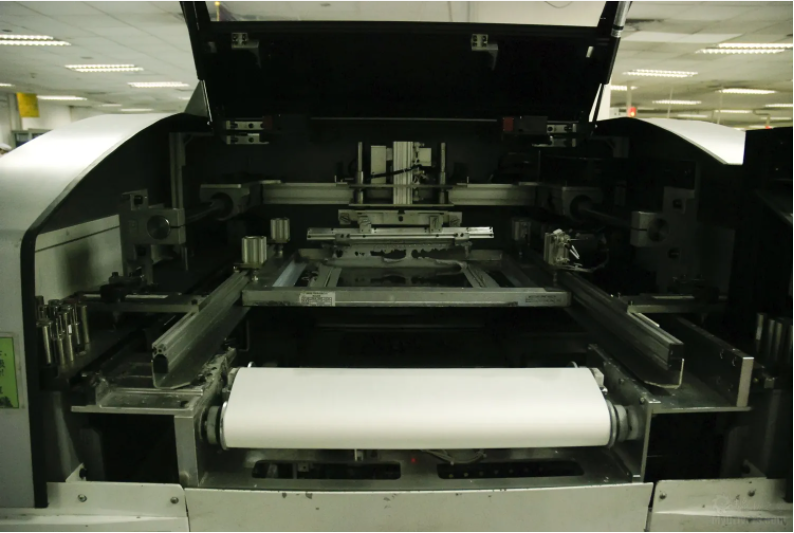

In the solder paste printing process, the printing machine is the key to achieve the desired printing quality. There are two main types of screen printing machines available today: laboratory and production. Each type has a further classification, because each company hopes to get different performance levels from the printing presses of the laboratory and production types. For example, the research and development department of a company uses the laboratory type to make product prototypes, while the production uses another type. Also, production requirements may vary greatly, depending on the output. Because it is impossible to classify laser cutting equipment, it is recommended to choose a silk screen machine that is suitable for the desired application.

In the manual or semi-automatic printing machine, the solder paste is manually placed on the laser steel mesh, and the printing scraper is at the other end of the steel mesh. In the automatic printing machine, solder paste is automatically distributed. During the printing process, the printing scraper presses down on the SMD steel mesh to make the bottom surface of the steel mesh contact the top surface of the circuit board. When the scraper passes through the entire length of the corroded graphic area, the solder paste is printed on the bonding pad through the holes in the laser steel mesh.

After the solder paste has been deposited, the wire mesh is immediately detached after the scraper and returns to the original place. This interval or separation distance is determined by the equipment design, about 0.020 “~0.040”. The separation distance and scraper pressure are two important variables related to equipment to achieve good printing quality.

If not, this process is called contact printing. Contact printing is used when all metal stencils and scrapers are used. Non contact printing is used for flexible wire mesh.

2) Scraper type

The abrasion, pressure and hardness of the scraper determine the printing quality, which should be carefully monitored. For acceptable printing quality, the scraper edge should be sharp and straight. Low scraper pressure will cause missing and rough edges, while high scraper pressure or very soft scraper will cause spot printing, and may even damage the scraper and steel mesh. Excessive pressure also tends to dig out solder paste from wide openings, resulting in insufficient solder fillets.

There are two common types of scrapers: rubber or polyurethane scrapers and metal scrapers. When using a rubber scraper, use a scraper with a hardness of 70-90 rubber hardness tester. When the pressure is too high, the solder paste that seeps into the bottom of the steel mesh may cause a tin bridge, which requires frequent bottom wiping. To prevent bottom penetration, the pad opening must provide a sealing function during printing. This depends on the roughness of the steel mesh opening wall.

Metal scraper is also commonly used. With the use of more closely spaced components, the amount of metal scraper is increasing. They are made of stainless steel or brass, have a flat blade shape, and use a printing angle of 30-45°.

Some scrapers are coated with lubricating material. Because of the low pressure, they will not dig out the solder paste from the opening, and because they are metal, they are not as easy to wear as rubber scrapers, so they do not need to be sharp. They are much more expensive than rubber scrapers and may cause mesh wear.

The use of different scraper types is differentiated in the printed circuit assembly using standard components and pin elements. The requirements for solder paste amount are very different for each component. Tightly spaced components require much less solder than standard surface mount components. The pad area and thickness control the amount of solder paste.

Some engineers use a double thickness steel mesh to apply the appropriate amount of solder paste to the foot elements and standard surface mount pads. Other engineers take a different approach – they use more economical metal scrapers that don’t need to be sharp all the time. It is easier to prevent the change of solder paste deposition with metal scraper, but this method requires an improved steel mesh opening design to prevent excessive solder paste deposition on closely spaced pads. This method has become more popular in industry, but the rubber scraper with double thickness printing has not disappeared.